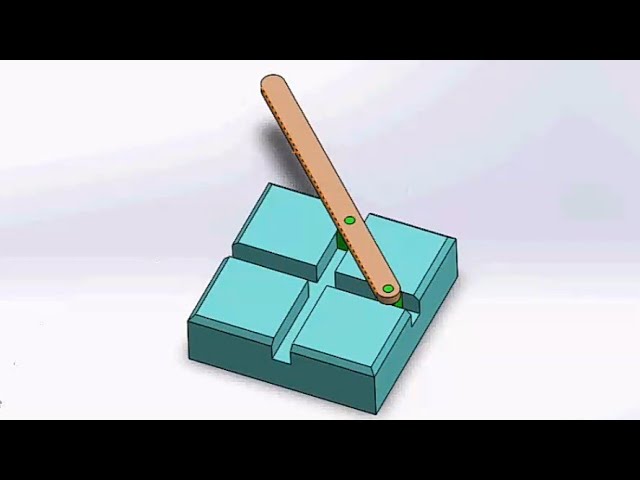

Double Slider Crank Mechanism

Class: Intro to Engineering and Design

Design the Mechanism:

- I sketched my design, focusing on dimensions and the motion path.

- I chose materials based on my design, considering what I have available.

- I calculated necessary dimensions to ensure everything fits together properly.

Gather Tools and Materials:

- I collected the tools I needed: a drill, saw, screwdriver, ruler, and protractor.

- I gathered materials like plywood, metal sheets, rods, bearings, and screws.

Fabricate the Crank and Slider:

- I cut the crank arm and made sure to include a pivot point.

- I created the slider from a block or rod that would move along a guide.

- I drilled holes for the pivot and the connecting rod attachments.

Build the Frame:

- I constructed a stable base using my chosen material.

- I installed guides for the slider, ensuring they’re aligned for smooth motion.

Electronics and Motion Setup

- I designed specific movement within the CAD software to insure that the product moved smoothly.

Assemble the Mechanism:

- I attached the crank to the frame at the pivot point.

- I connected one end of the connecting rod to the crank and the other end to the slider.

- I placed the slider in the guide rail and checked that it moves freely.

Test the Mechanism:

- I manually rotated the crank to see if the slider moves smoothly.

- I identified any issues, like binding or misalignment, and adjusted as needed.

Optimize and Finalize:

- I applied lubricant to the moving parts to reduce friction. I made any necessary adjustments to improve performance.

- I documented my work with notes and photos for my project report.